High Performance Plastics

Polyimide (PI) is a very suitable plastic for high temperature applications. The most important structural attribute of these high performance plastics is the group of imides. Polyimide is produced by polycondensation out of tetracarbonaciddianhydrids and diamines. For polymer chains containing aromatic components, polyimides are preferred when used with high temperatures.

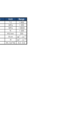

Properties

- temperature resistance up to 400°C

- very resistant to deformation

- very high electrical strength

- suitable for high frequency

- isolating due to high electrical resistance

- resistivity to many chemicals

- low flammability

- resistivity to radiation

- low fumigation

- Disadvantage: relatively high water absorbing capacity of 3 to 5%.

Applications

Polyimide and polyamidimide are mainly used for producing seamless belts with or without subsequent coating. Based on many years of development work, we can now produce individual polyimid tubes/belts up to a diameter of approx. 500mm and a width of approx. 2m. Layer thickness up to 0,1 mm are no problem. The special material properties for the various applications such as electrical conductivity or insulation, thermal insulation or conductivity, antiadhesiveness or high mechanical stress can be individually adjusted. Additional polymer or Teflon layers can be applied through various processing methods to support certain desired properties and according to customer's specification.

- Digital printing machines

- Digital overprinting devices

- Batterie or sensor insulation

- Aircraft industries

- Heater insulation, high temperature sheath

Deutsch

Deutsch